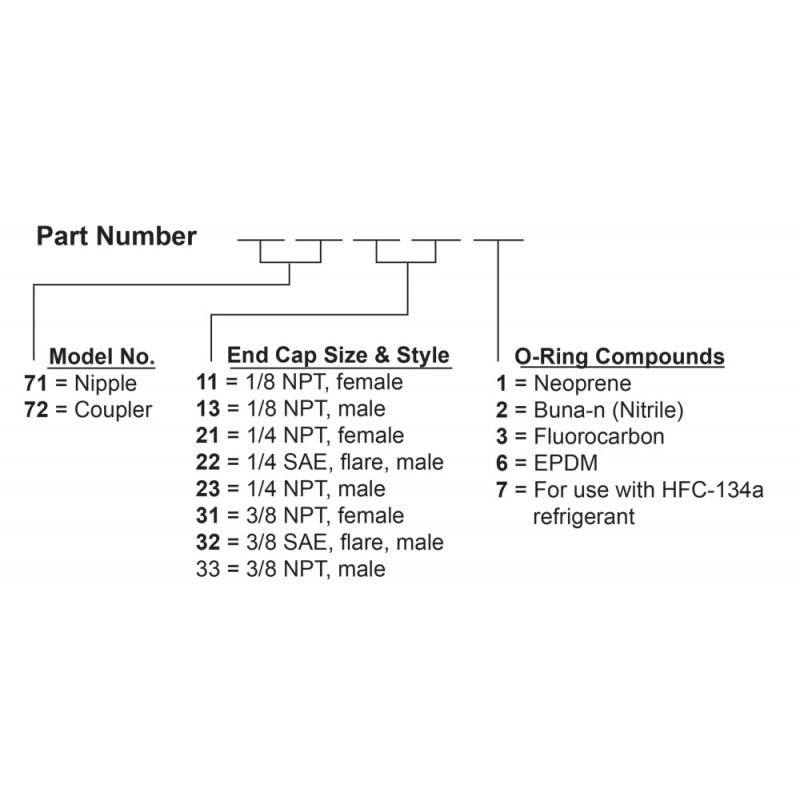

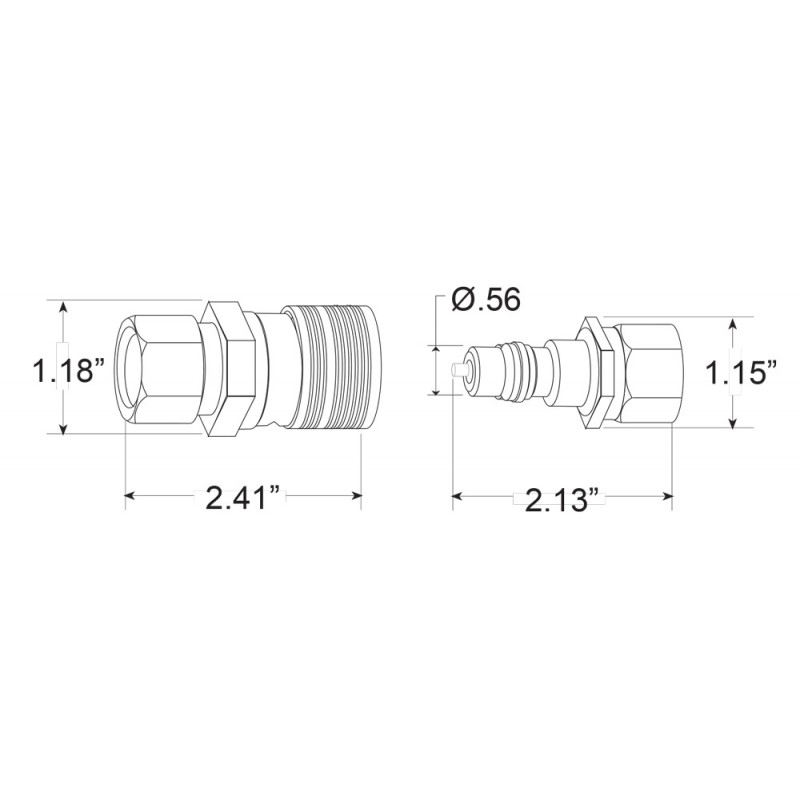

The Models 71 and 72 Nipple and Coupler assemblies have an improved seal design. Field testing has shown that this design will offer longer life and better compatibility characteristics with blended refrigerants and ester oils. They will provide positive leak-tight shutoff and will hold pressures from vacuum to 1000 psig.

These tough, lightweight PCU Couplers and Nipples utilize heat-treated parts for interchangeability and long life. They provide a large unrestricted flow rate (0.7 Cv) for a variety of production uses, while minimizing process material loss during coupling and uncoupling, within a temperature range of 0° to 250°F.

An eight (8) ball detent lock provides instant positive coupling. Simply pull back the grooved locking ring on the coupler, slide the coupler over the nipple, and push together until the lock ring snaps to its “lock position”.

The standard Series 250 Models 71 and 72 Nipple and Coupler assemblies are built using neoprene seal material. We recommend our standard products for processing R-22, R-410, R-404-A and compressed air.

If currently using the Series 250 Model 61 Nipple or Model 62 Coupler, inexpensive kits are available which can easily be retrofitted. This allows you to take advantage of this design improvement.

When vacuum and ester oils are being used please contact our Order Department at (937-299-5594) for help in selecting the correct elastomer for your particular application.

The Series 250 Models 71 and 72 Nipples and Couplers complement our Series 50, 500, 91, and 93 Tube Quick Connect (TAC) Couplers to permit unrestricted flow.