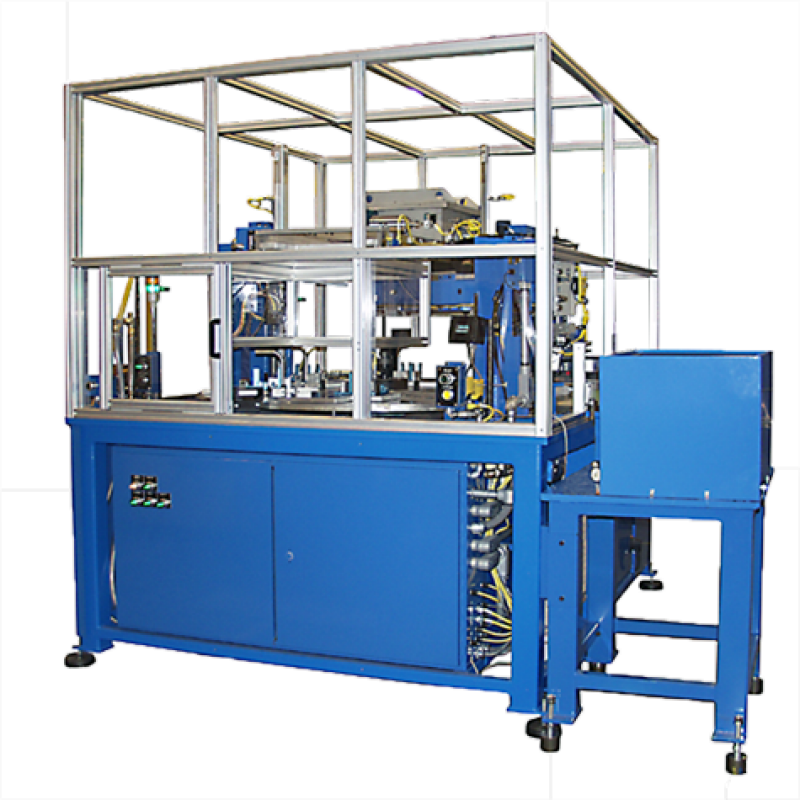

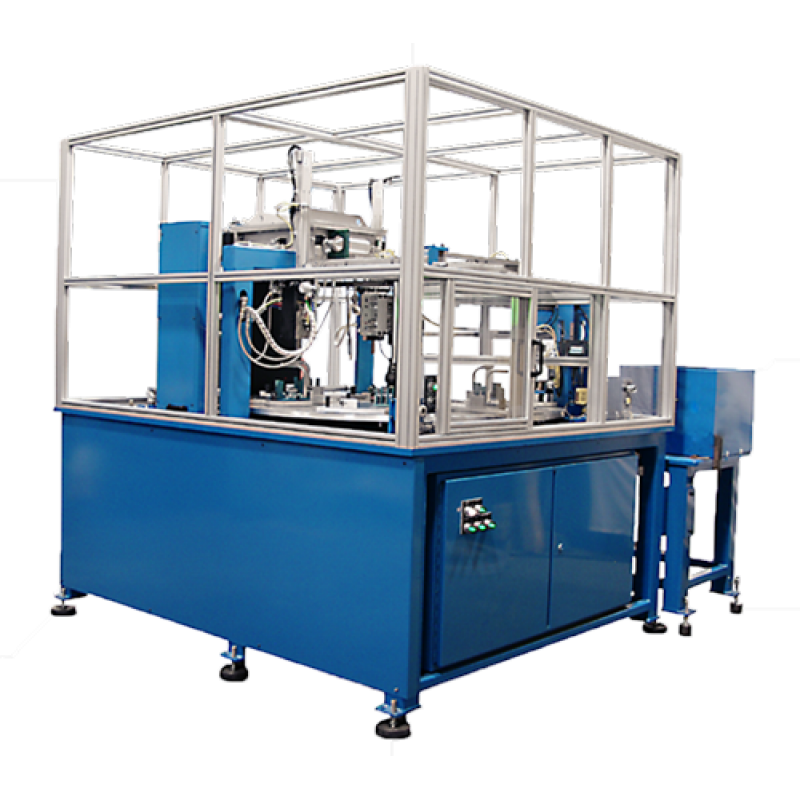

The PCU Rotary Index Table is a combination assembly and test center. This system embodies PCU’s field proven testing technology with automated component part assembly in a compact industrial design simplifying operator tasks. The result is a durable and dependable operation with accurate and repeatable process control. The operator interface panel allows the technician to view the cycle status as it progresses. Once the system is configured, the operator is only required to load/unload the product and initiate the table index.

The rotary index table is setup so that the early stations are utilized for component assembly and the latter stations utilize various testing technologies to verify the assembly’s integrity and may perform a final fluid fill. Each station is designed for independent operation and is able to be individually configured.

Typical configuration consist of a pressurized air supply for articulation and operation along with a 460/3/60 power supply to minimize system current draw. The component assembly stations are fed with bowl feeders and configured with a pick and place arm. The assembly is then fed into an integral mass spectrometer for ultra fine leak testing. The mass spectrometer utilizes a high vacuum chamber to facilitate the automated leak test. After part leak test is complete, the helium is removed from the part and the part is prepared for final fluid fill. The final stages are used to check the completed assembly with vision systems and run testing. Finally, the part may be removed from the index table manually or with an automated articulating assembly.