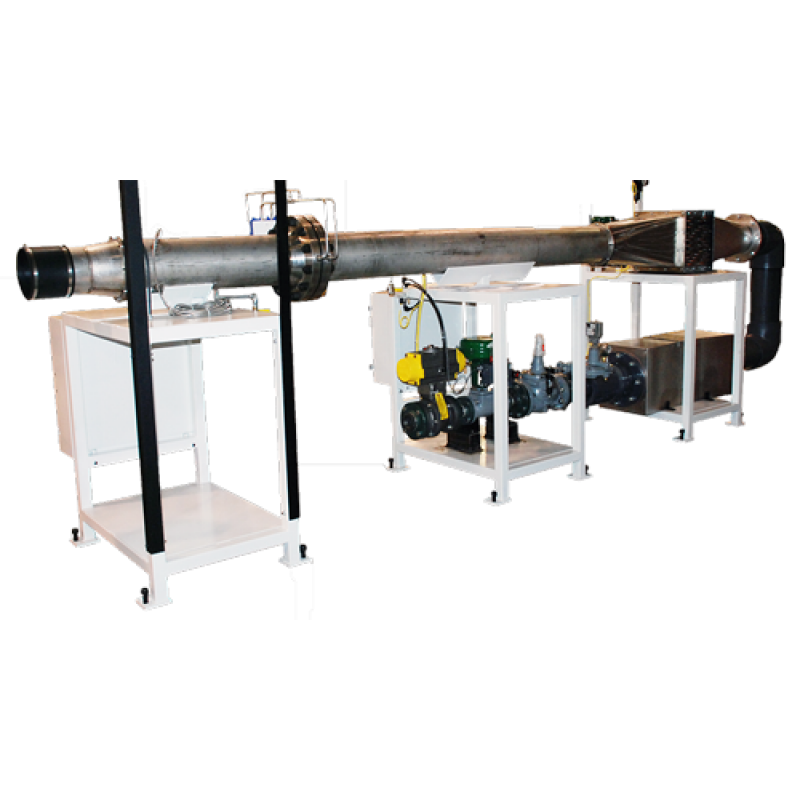

The PCU Wind Tunnel is designed to provide various thermal loads to any thermal management system for fully loaded dynamic testing. This system combines PCU’s field proven testing technology with the flexibility to match a wide range of thermal requirements. The test system employs an operator interface which allows the specified control properties for thermal loading to be adjusted without reconfiguring the system. Utilizing the latest in PID controls, the system is able to provide a fully flexible operation with accurate and repeatable process control. Once the system is configured, the operator is only required to load/unload the product and initiate the testing.

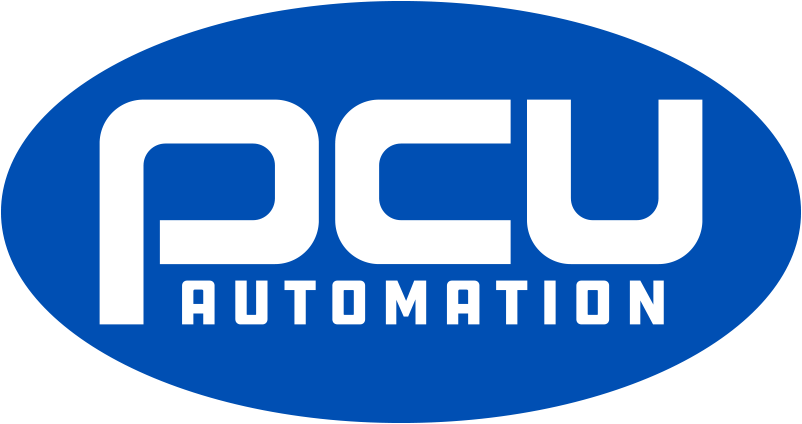

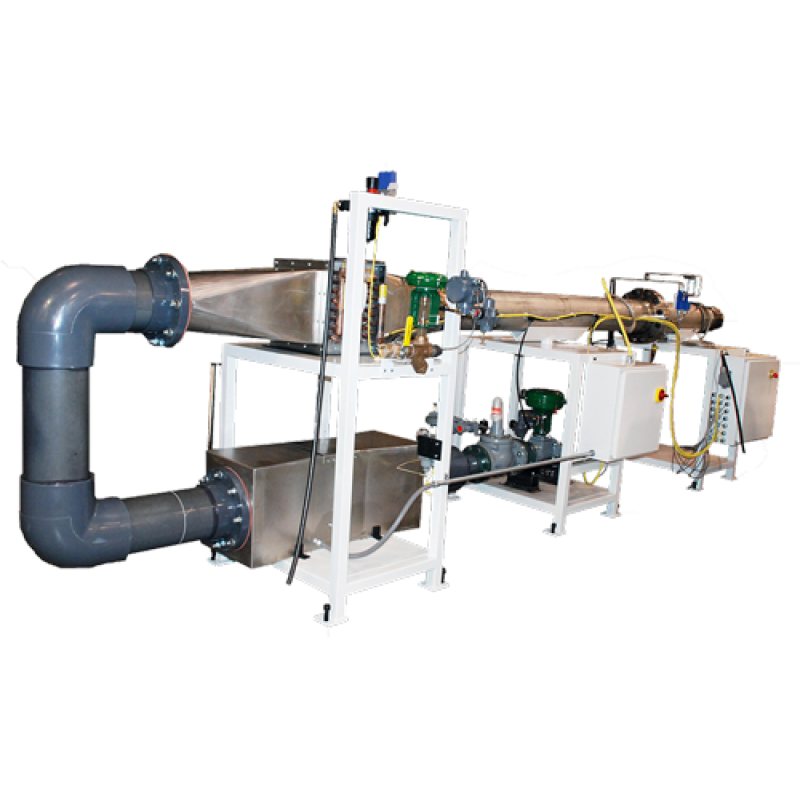

In addition to the wind tunnel, the test system can also be configured to supply liquid utilities as required to dissipate any thermal needs. The test system also includes data collection which can be utilized to log inlet/outlet conditions along with temperature profiling as needed. Depending on the specific needs, the wind tunnel can be set up for either open or closed loop operation.

Typical configurations consist of a tunnel with a flow meter, proportional flow control valve and or a blower to provide the required mass flow. The flow is conditioned with dryers, chillers or heaters as required conditioning the mass flow before and after the test station. Chillers and heaters along with proportional valves are, also, used to provide liquid mass flow at the desired levels for secondary flow management. The test may be run from several minutes to several hours. Additional power utilities required are a compressed air supply and 460/3/60 electrical power.