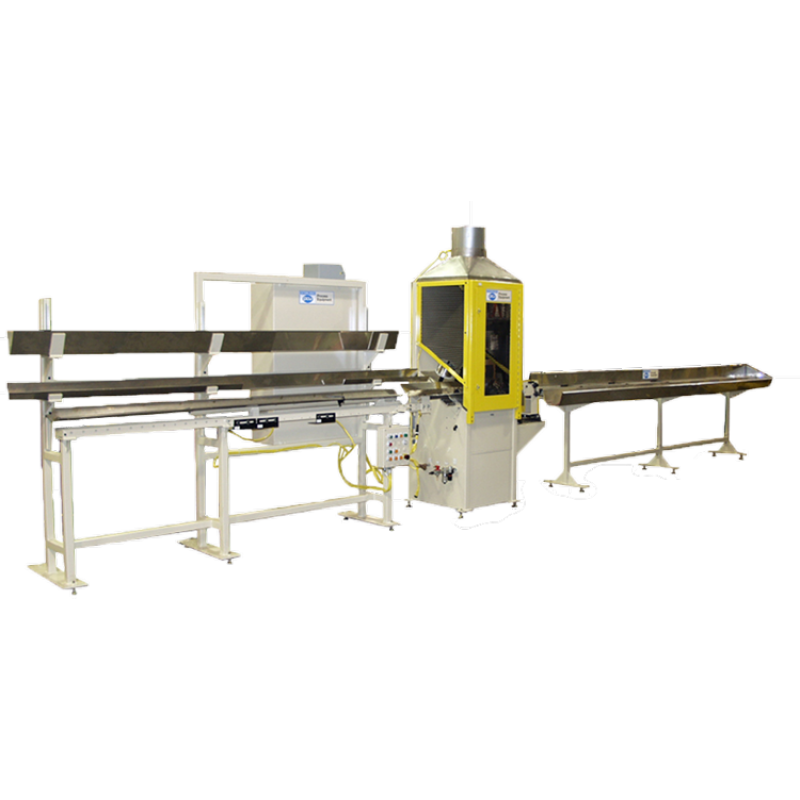

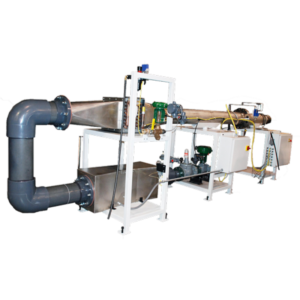

The PCU Soldering Machine provides high production rates and consistently solders capillary tube and suction line assemblies. Using an oxygen/acetylene, oxygen/natural gas, or oxygen/propane gases flame, the machine is capable of turning out 100 to 200 soldered assemblies per hour depending on length of assembly, length of soldered joint and diameter of suction line. PCU soldering machines are custom-designed to the user’s specifications depending on the individual application. The machine can be configured to solder capillary tubes of 1/4 5/16″ or 3/8″ diameter. Tube feed rate is adjustable from 120 to 400 inches per minute. The machine is PLC controlled with customer choice of PLC type and displays for machine program setup.

Use of the PCU soldering machine only requires the operator to take the straight pre-cut capillary tubing and suction line from the supply rack place them into the carriage on the loading table clamp them into position and push the leading ends into the soldering section of the machine. The rest of the operation is completely automatic. The soldering assembly is fed from the machine and deposited onto a storage tray. It is not necessary for the operator to come near the soldering section of the machine at any time.”